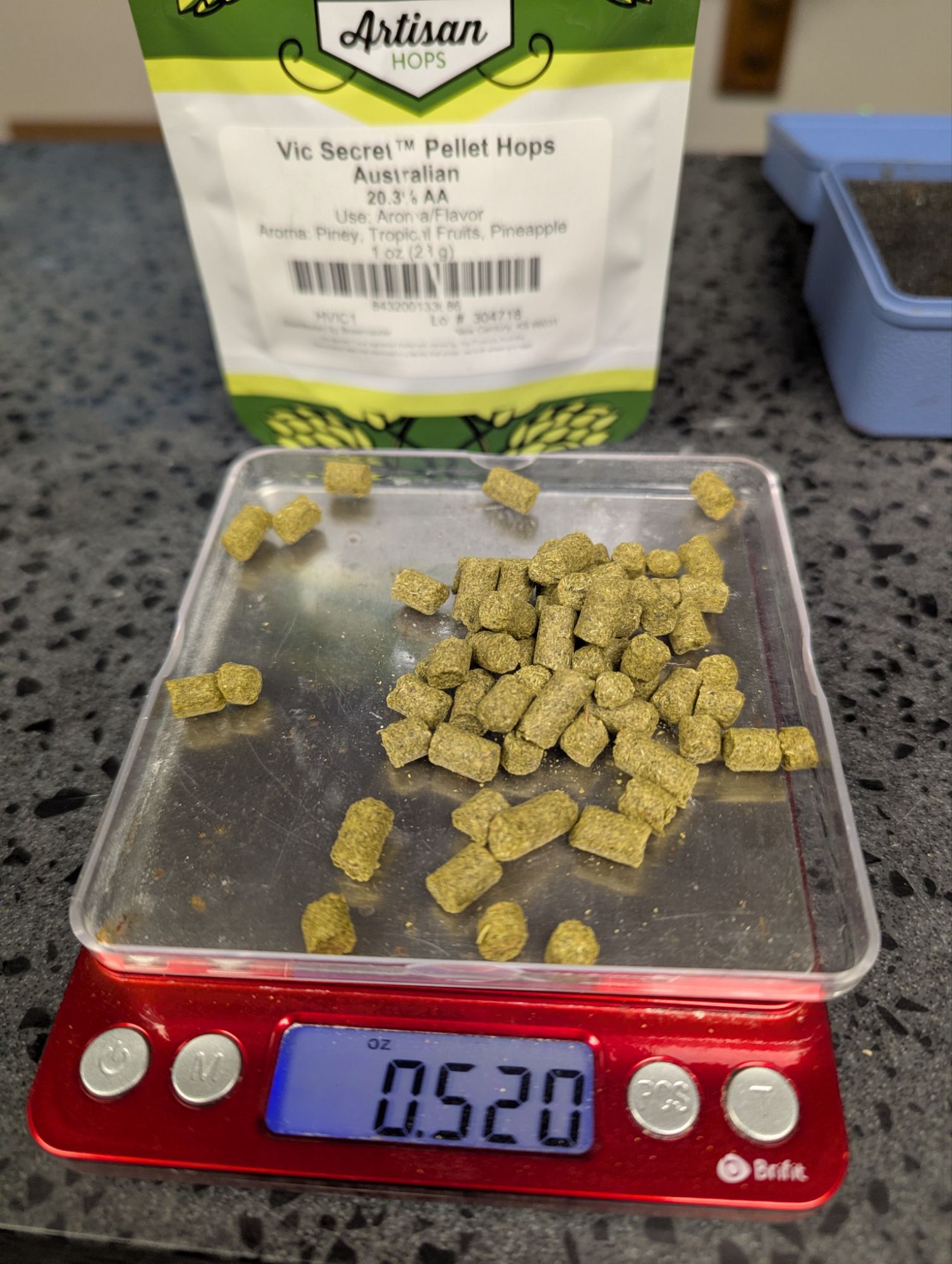

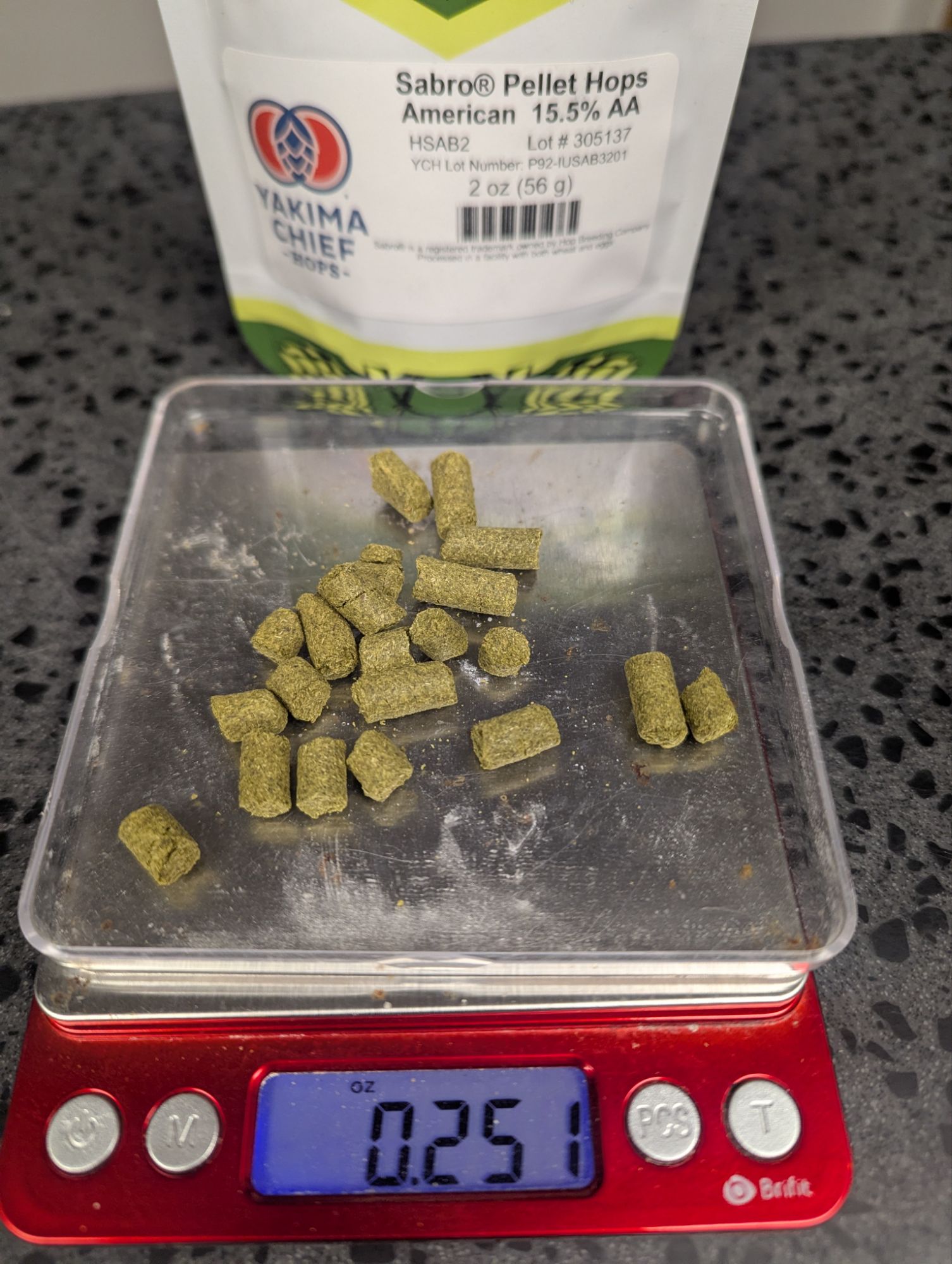

So as some of you may know or remember reading from another post, I listen to the HomeBrew Happy Hour pod cast. They had decided to do a Kolsch Cup in which any Patreon member could submit for free. So why not, I really need someone opinion on how I’m doing, outside my circle of friends. I had put together a very basic recipe based on the BJCP guidelines. One thing I did and never used before was White labs yeast. I mainly use Imperial because of the double count of cells they have.

So brew day went well, I think during this brew session I was over thinking everything because I knew it was going to be judged. I did some things I have never done before during this brew session which included a step mash with a PH rest, additional one of the first times using RO water and making the salt adjustments. So probably not the best time to start to try different things. After trying the step mash I will not be doing that again, I didn’t see any benefit to doing it, and from what I read a lot has to do with the highly modified grains used today so step mashing isn’t needed. I thought it might give some complexity to the beer.

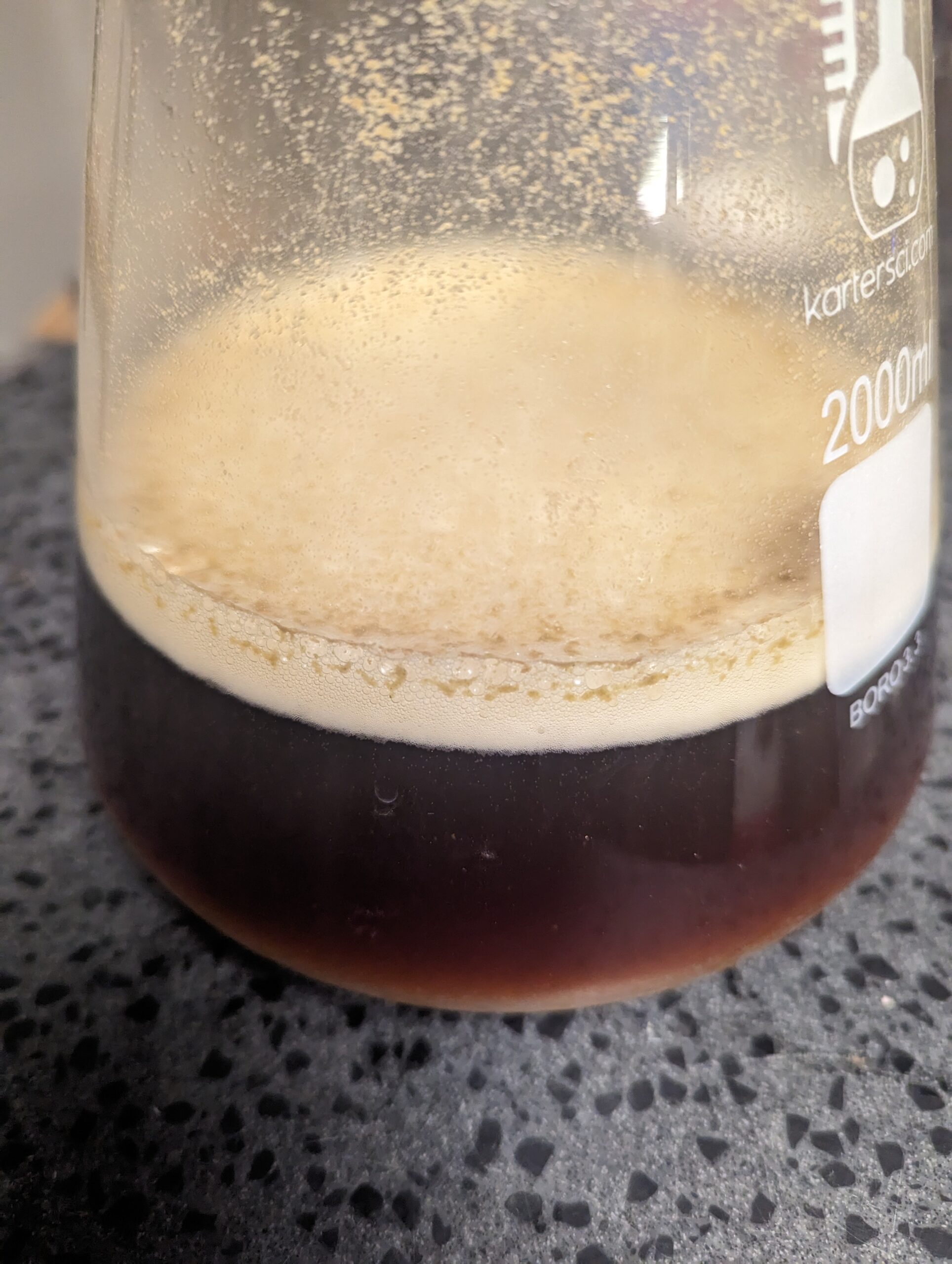

Brew day went overall well, as I thought, pitched the yeast and waited. I’m use to yeast kicking right off in under 8 hours but this lagged behind and took a little over 24 hours to kick off and I was a little nervous about this. I had made a note if using White Labs in the future, I need to do a starter. Kept at a low 62 degrees and once about 3/4 finished I tried to moved up to about 68 degrees to clean out but had difficulties as it was extremely cold out and basement temps were hard to keep warm, Not sure if I ever went higher than 65. Once I hit FG (1.008) I cold crashed for a little over a week. Now one thing I had never done on this beer was taste it. I had so much on tap I didn’t think about it. I performed the wait-force carb method, which is just hook up gas set to 12 PSI and wait.

After a few weeks on gas it was time to bottle. I have a new counter pressure bottle filler that I have bottle a few beers on but nothing that was going to have to wait a few weeks before tasting so I ended up bottling up about 20 beers and I picked the two of them filled to perfection and also pulled two aside to taste on the day of the tasting. Those two I pulled out for myself for later I ended up storing at 70 degrees for a few days to mimic the travel to Texas for the competition.

At this point I still didn’t taste the beer. Now its the day of the competition and when I got home from work I cracked one of those Kolsch’s and tasted it. How said was I to taste green apple, also known as Acetaldehyde, an off flavor. Man where did I go wrong on this brew. Well the off flavor isn’t bad and works but its not what I wanted at all in my brew. While watching the tasting I happen to hear my beer # and the first comment was, taste like green apple 8(. Hey this is how you learn and grow in brewing. So what caused this???

That is the question What causes Acetaldehyde and how do you prevent it. So I dug into Acetaldehyde to figure out what causes it, and how to get ride of it during a brew. Some ways to avoid this is posted below

- Maintain flawless sanitation practices.

- Pitch an appropriate amount of yeast.

- Fully oxygenate wort at pitching.

- Avoid racking beer off the yeast trub before fermentation is complete.

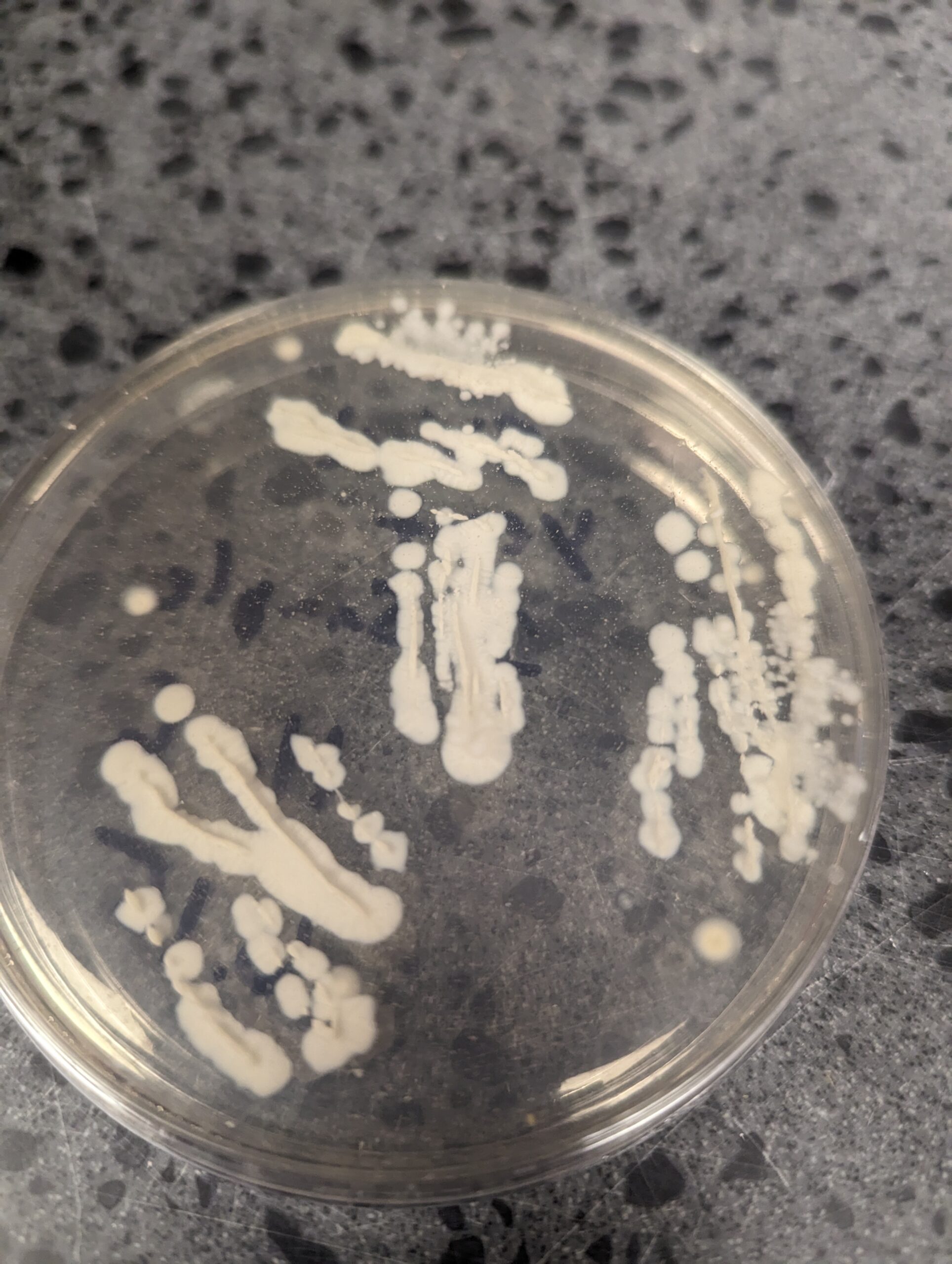

- Avoid introducing oxygen into your beer after fermentation.

Looking at the first one, Well I clean, clean, sanitize and sanitize so I don’t think this was an issue on this batch. All stainless equipment and easy to clean. The second one I feel may have been this factor. “Brewers yeast produces acetaldehyde as an intermediate compound in the conversion of glucose to ethanol, so it’s found in every beer you make, at least during primary fermentation. However, in a healthy fermentation, the yeast fully converts the vast majority of this compound to alcohol so that any residual amount falls below the flavor threshold. If the fermentation is less than optimal, the conversion of acetaldehyde to alcohol may remain incomplete, and too much will remain in the final beer.” This is where I think I was lacking on this beer. I used White labs yeast, which I never used before. I don’t want to know White labs but i’m just use to having more cell counts, but didn’t think of that at the time, and my dicetel reset wasn’t really there, as the temps where too cold. Third, I drop the wort from a good distance and always have a bunch of bubbles in my wort so I feel that I oxygenate enough. Fourth, I left the yeast on the trub for a while so pressure sure this wasn’t my issue and fifth, this could be the cause with my new counter pressure bottle filler maybe I pushed O2 into the beer but highly doubt that was my issue.

So to conclude, I feel that yeast was my issue and fermenting temps. When I go to re-brew this beer I plan on a yeast starter or go with my Imperial yeast that I love so much. I really need to get something like a brew belt during the winter months so I can perform my dicetel reset to clean up some of these off flavors during the fermentation. If it wasn’t for the competition I don’t think I would have noticed an issue as when your having a beer or two with friends your not really looking for the off-flavors or issues but going into a competition I sat there and looked at the same sheets the judges had so I’m now looking for issues. I hope this shows that its good to send a beer into a competition and take the feedback and understand what happened to better yourself for the next batch.

Brew On.