This is a kit I picked up at https://www.beer-wine.com/haze-craze-new-england-ipa-all-grain-kit-14946 Beer-Wine Hobby, who is right around the corner from me and need to use more. Got the s-04 as I don’t like getting liquid yeast in the summer months. Great people and even called to see if I wanted it milled or not, as I forgot to select it. Well the day before as it is a work day I collected 6.75Gallons (25.5L) of water and added in the salts per the recipe based on my water. Milled the grains and will start the timer in the AM before work.

@14:00 on 7-17-25 I started the unit and turned it up to 150F(65.5C). I got called in this morning for work so never setup the start time. Was able to leave a little early to get a jump. @14:54 and 144F(62.2C) I added in the grains and than my phone rank. I started the timer at 15:08. I realized I didn’t add the stop screen for the first 30 minutes and I gave the grain bed a good stir all the way down and placed the topper on to disperse the water better. With about 8 minutes left in the mash I turned the Anvil up to 168F(75.5C) and 100% to mash out. The recipe called for a 75 minute mash too long in my mind. @ the end of the mash the wort was up to 161F(71.6C) and pulled the basket and turned the Anvil up to 212F(100C) while the wort drains. Pulled a wort sample of 1.047 SG after it hit 200F(93.3C) when I finished with draining and got 6 gallons (22.7L).

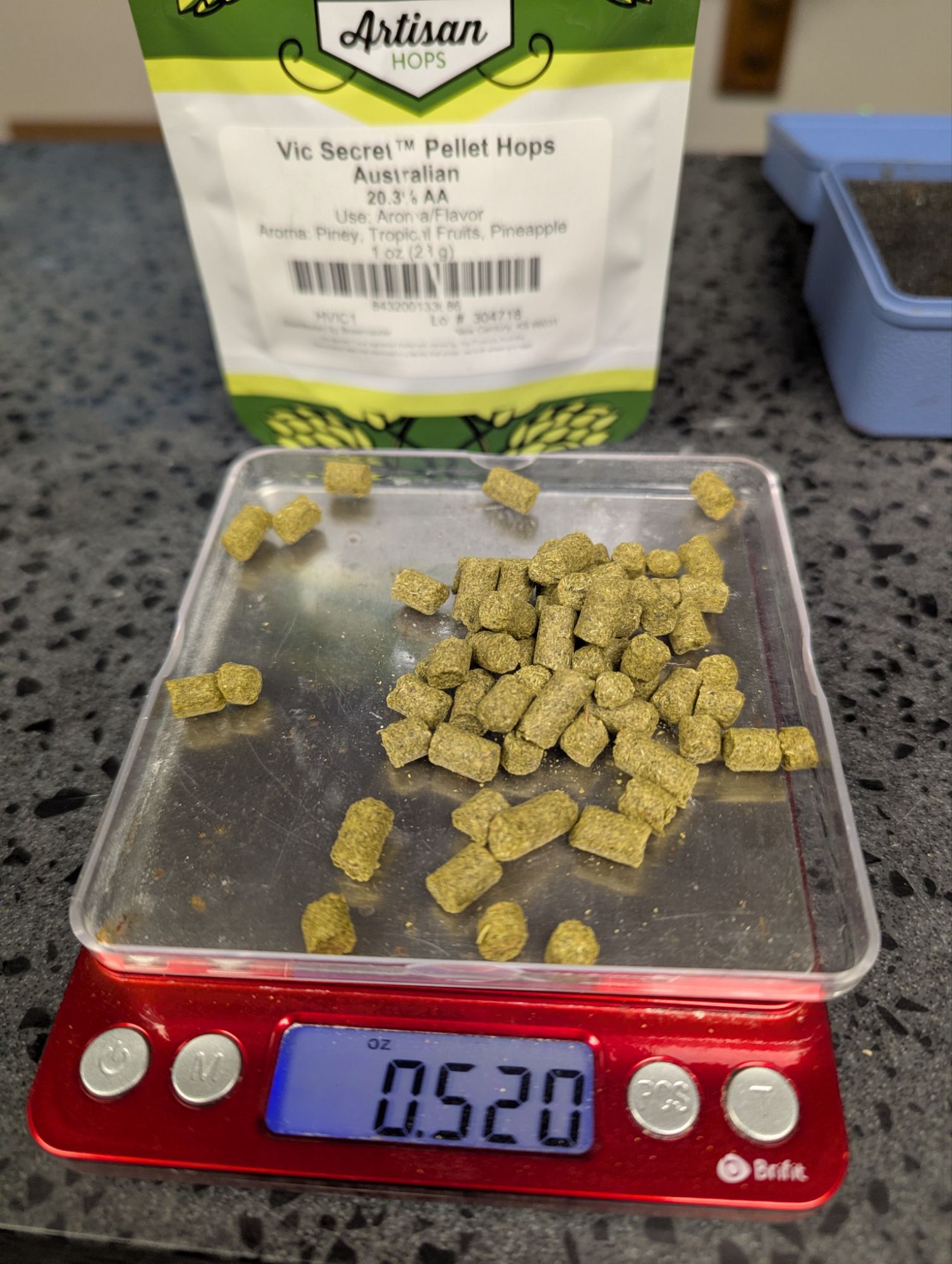

@16:57 the boil started and nothing to add till the 45 min mark and Ill toss that into the boil not the hop spider. This is my kinda recipe too, not much to do till the end. Trying a few extra steps and after putting in my chiller I put the lid on it to help sanitize the upper part with hotter temps and seem to get a more vigorous boil. @ the end cooled down to about 195F(90.5C) and tossed in the hops. Also pulled a wort sample with a sanitized syringe. After about 10 minutes at the 195F(90.5C) continued the cooling down. Wort came in at 1.050 SG and 5.5 gallons of wort. @18:21 wort was down to 89F(31.6C). had the yeast pitched and into the keezer at 80F(26.6C) to cool down to 68F(20C) @ 18:30 and call cleaned up by 18:39

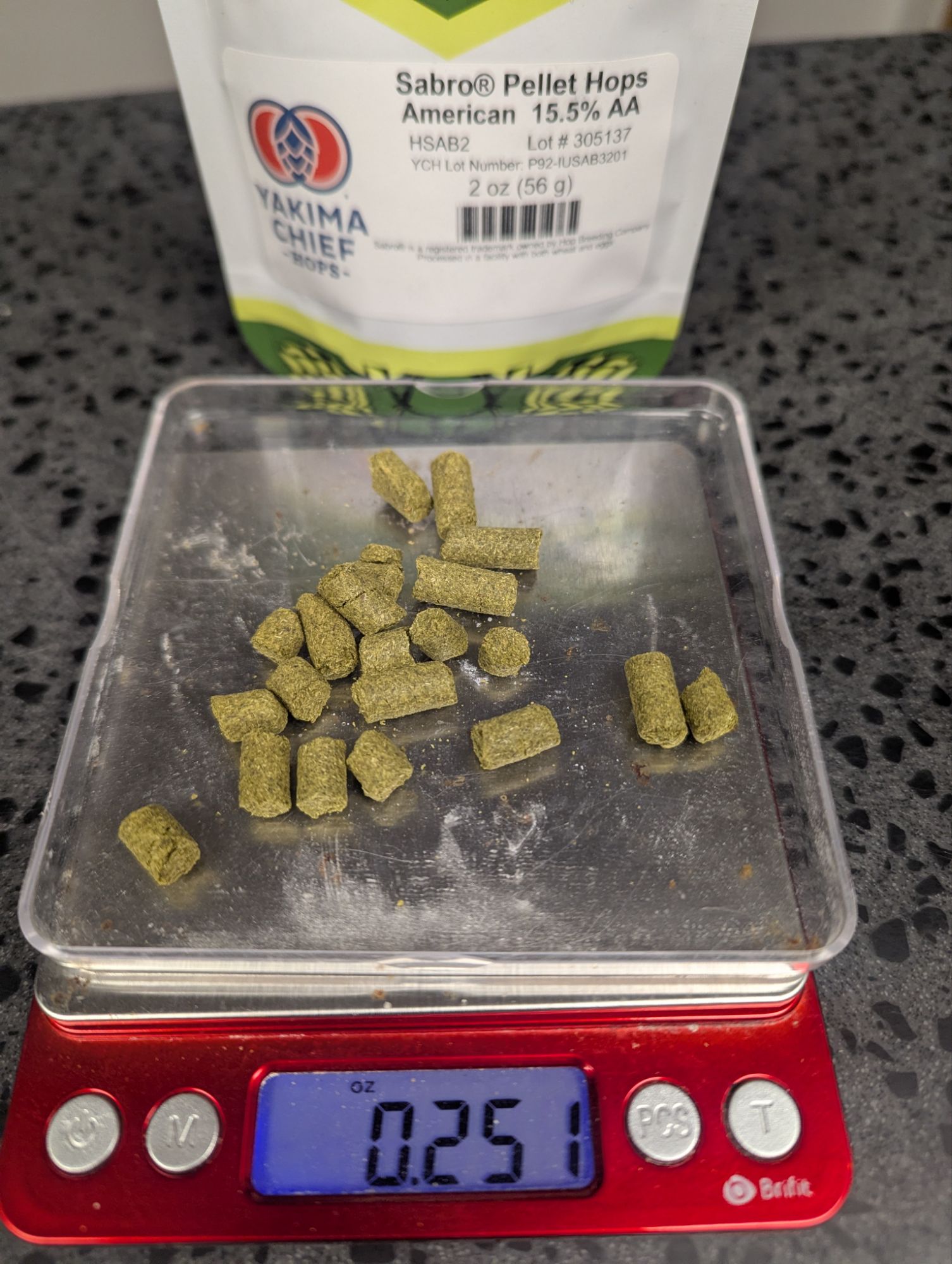

@06:40 on July 21st I pulled about 200mL of yeast slurry out of this batch to add to my fermentor of another batch of beer I’m brewing. Also added in the dry hops after. Luckily with the bag attached no air was sucked back, of course picked up a little bit when I dry hopped.

@08:07 on July 28th I transferred over the beer to the keg to carbonate I did start to drop the temperature slowly inside the keezer to 55F(12.7C) just to drop the hops out of the beer for easier transferring and it did. No clog this time. I did not rotate the rake till the end which maybe helped. Pulled a sample of 1.006SG and this beer tastes really good, Can’t wait for it to be really cold and carbonated.