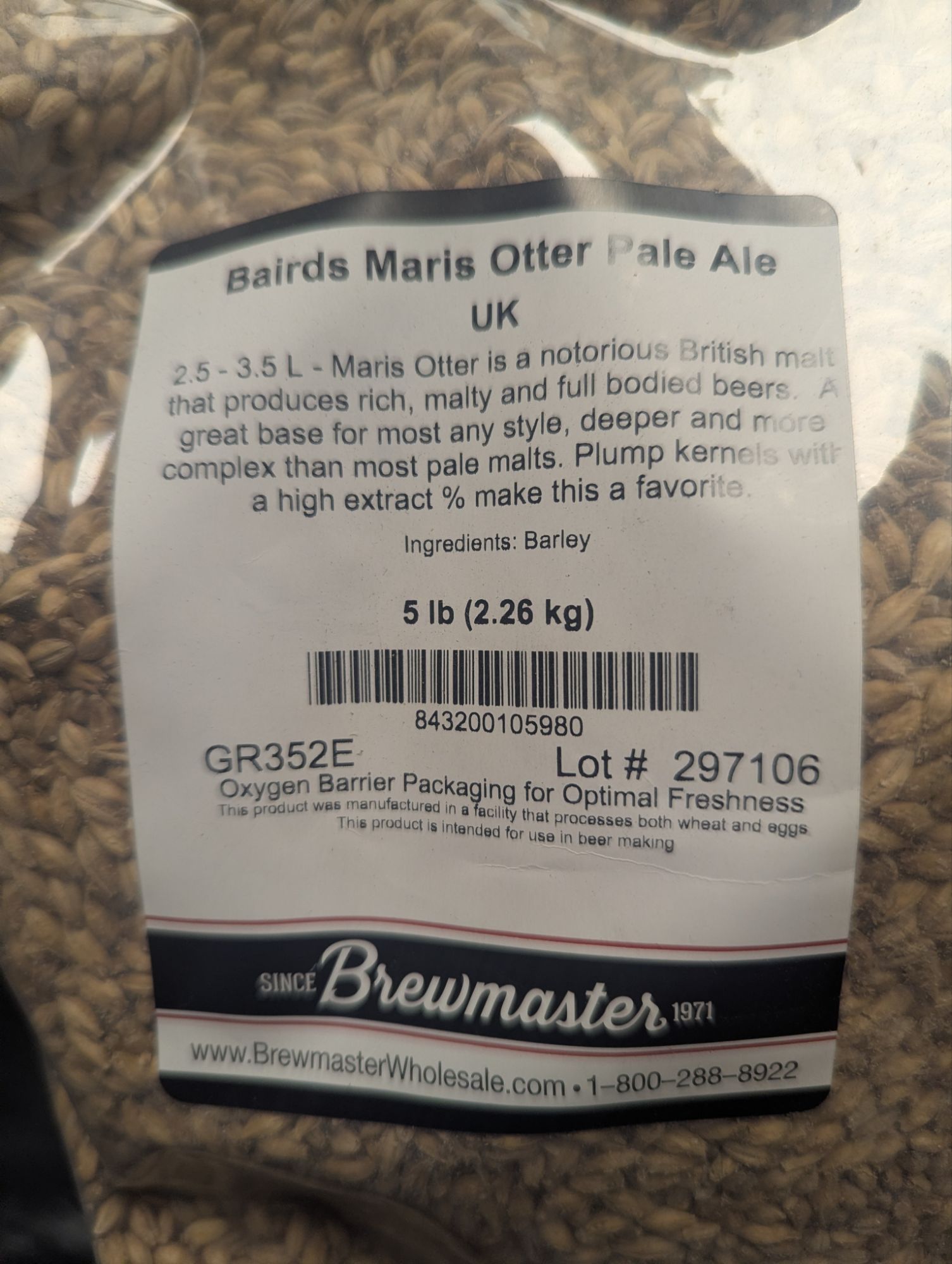

So like most brew days my brew day starts off the night before collecting all the RO water needed. Ill also mill the grains and setup my Anvil Foundry to start heating the water around 5:30am. I love a good early morning brew 8).

This is the one thing I love about the Foundry and being able to setup everything so when I wake up in the morning, I get my cup of coffee, feed the dogs, let them out, and head on down to the brewery to see the water is at the nice 150F and ready to dough-in.

After dough-ing in setup the pump and started to circulate the wort for the next 60 mins. About 30 minutes into the mash, I stopped the pump and gave it a quick stir. I don’t go all the way down but go down pretty far. With the bag it filters it very well. With about 7 mins left of the 60 minute mash I cranked the unit up to 168F and 100% power for a mash out which will be about 15 minutes at 168F.

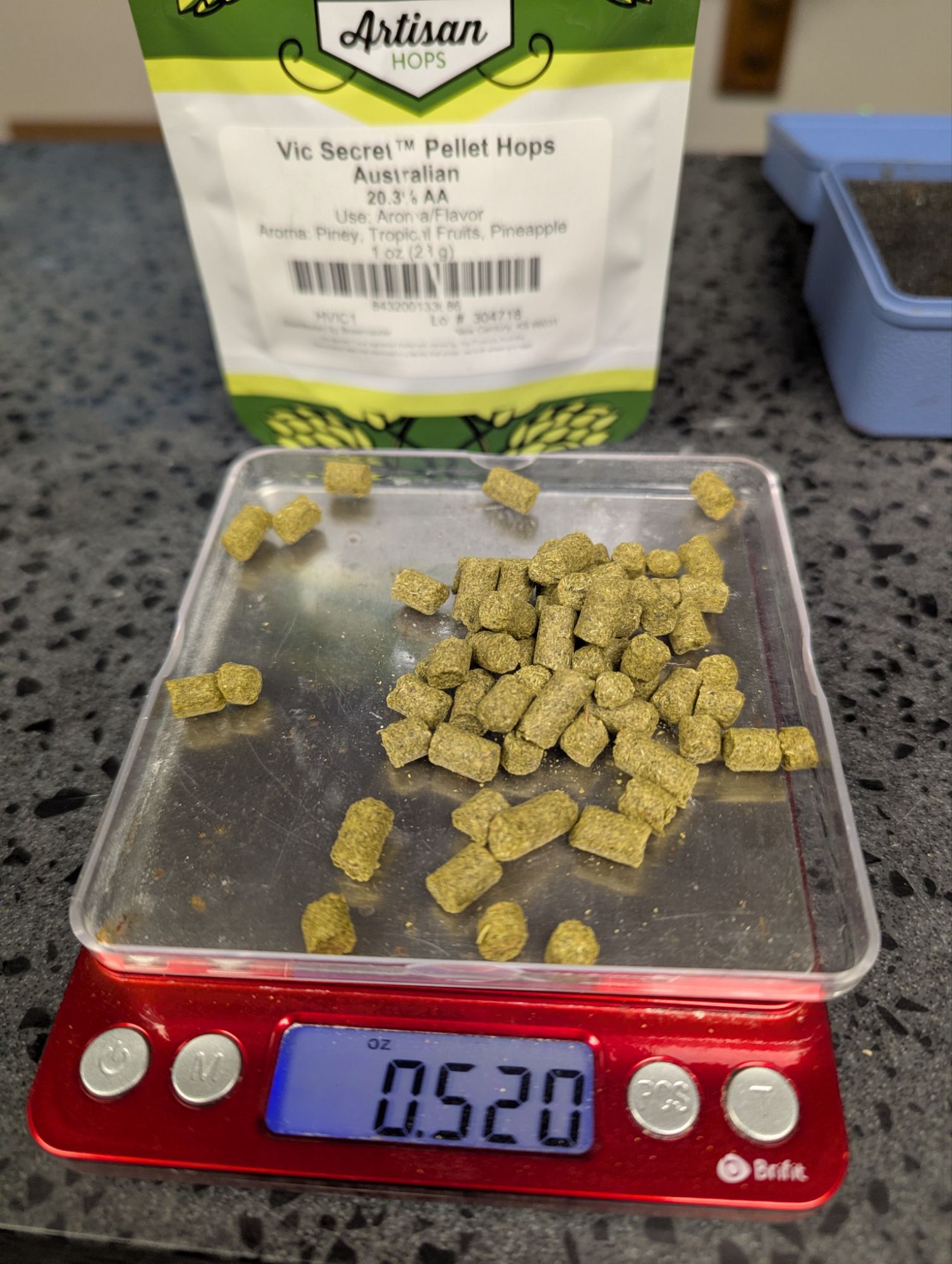

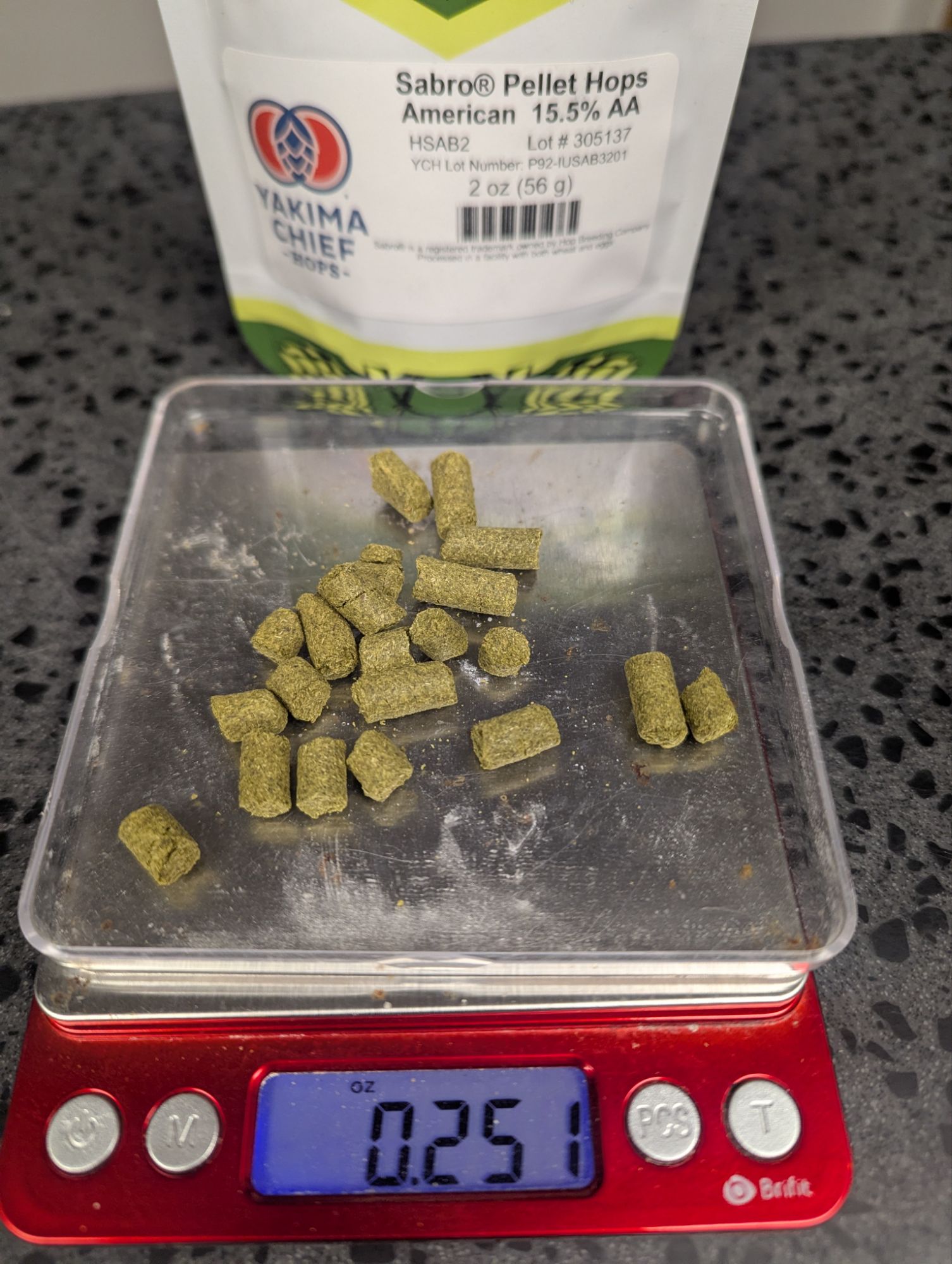

After the mash out, removed the grains and cranked the Foundry up to 100% 212 and let it go. Once I hit the boil started the 60 min addition and ready to go per the hoping schedule.

After boil was over, chilled down quickly to about 74 degrees and transferred to the fermentor. Ended up not having any w34/70 and ended up pitching Imperial’s Harvest yeast. Put in fermentation chamber and set for 58 degrees and the wait …….

UPDATE: As the brew was fermenting about a few days into it I started to raise the temperate up a few degrees and finally got to about 66 degrees. At that point took a gravity reading and added in the dry hop and set my freezer to 45 degrees. Crashed the brew down to 45 and then stepped it down to 38 over the next few days.