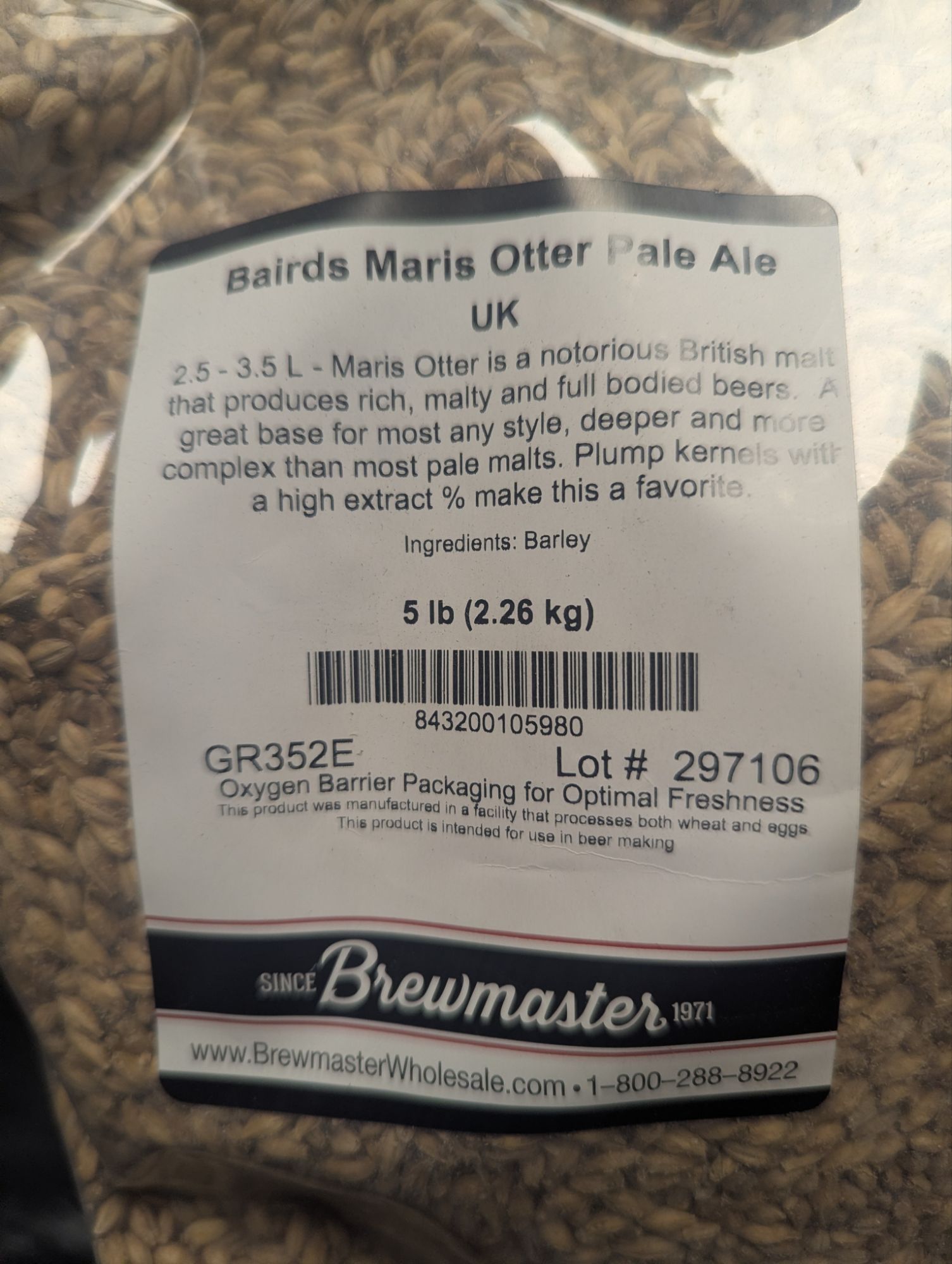

Collected the 7 gallons(26.5L) of RO water the night before and milled the grains. Added in the required salts and set the timer on the Anvil Foundry to start the heater @5:00 so by the time I get up @6:00 I’ll be ready to dough in. Foundry was setup for 158F(70C).

@6:17 I started to dough in @6:20 started the mash timer for 60 minutes. @6:50 gave the mash a good stir. I did end up going on the way down to the bottom. Did this to make sure we get good conversion as its a low ABV and want to make sure its not too low. @7:23 I lost track of time, bumped up the temperature to 168F(75.5C) and pulled the grains, going to skip the mash out. Once the wort stopped draining I pulled the basket and placed it at an angle to help the rest of the wort run out. Pulled grains and cleaned equipment that I’m done with, basket, lid, and strainer. Pulled a wort sample to tested and got 1.040SG and 6.4G(24.2L) of wort. @8:02 I pulled 1.25 cups(300mL) of hot break when the wort hit 200F(93.3C).

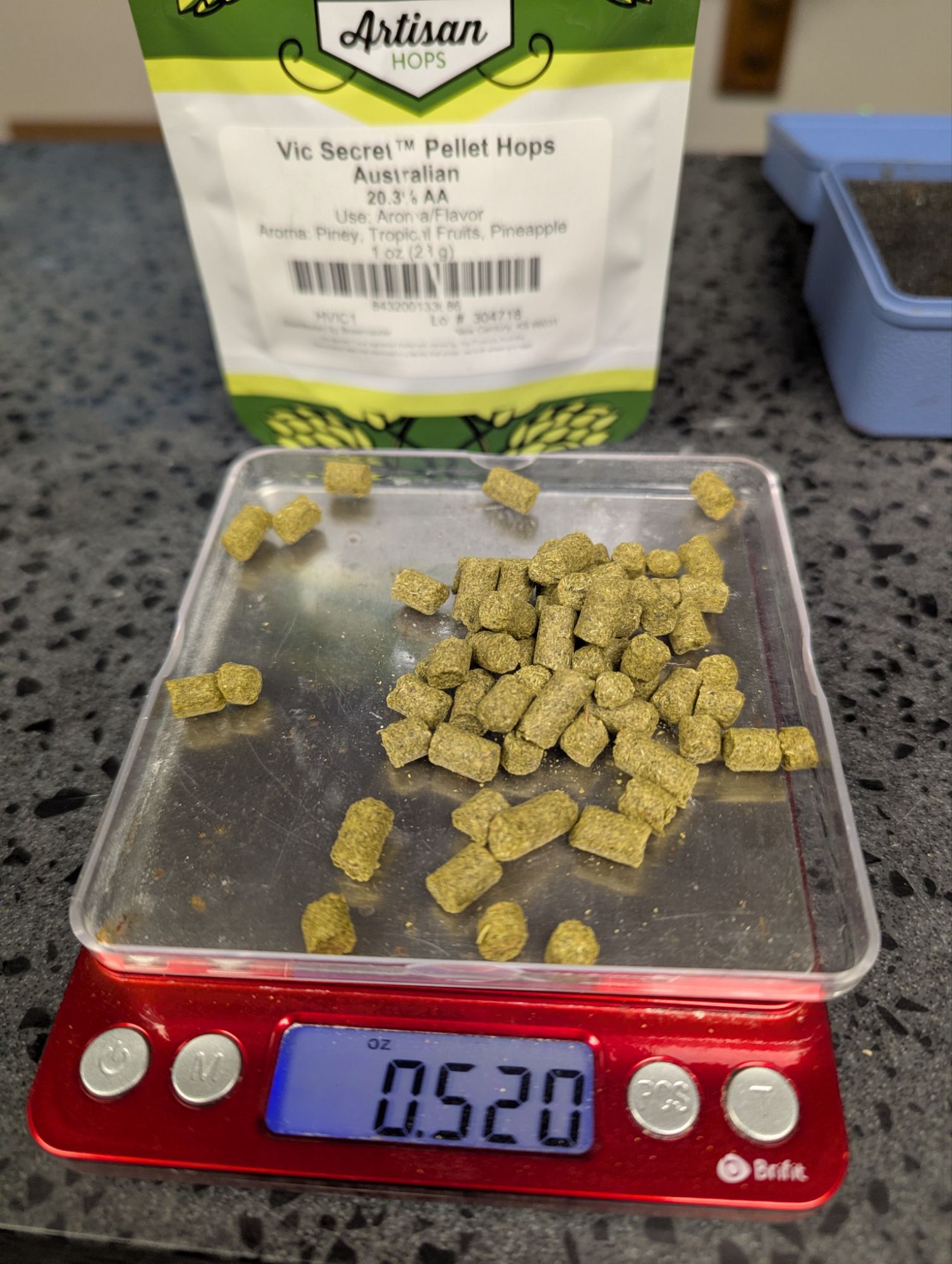

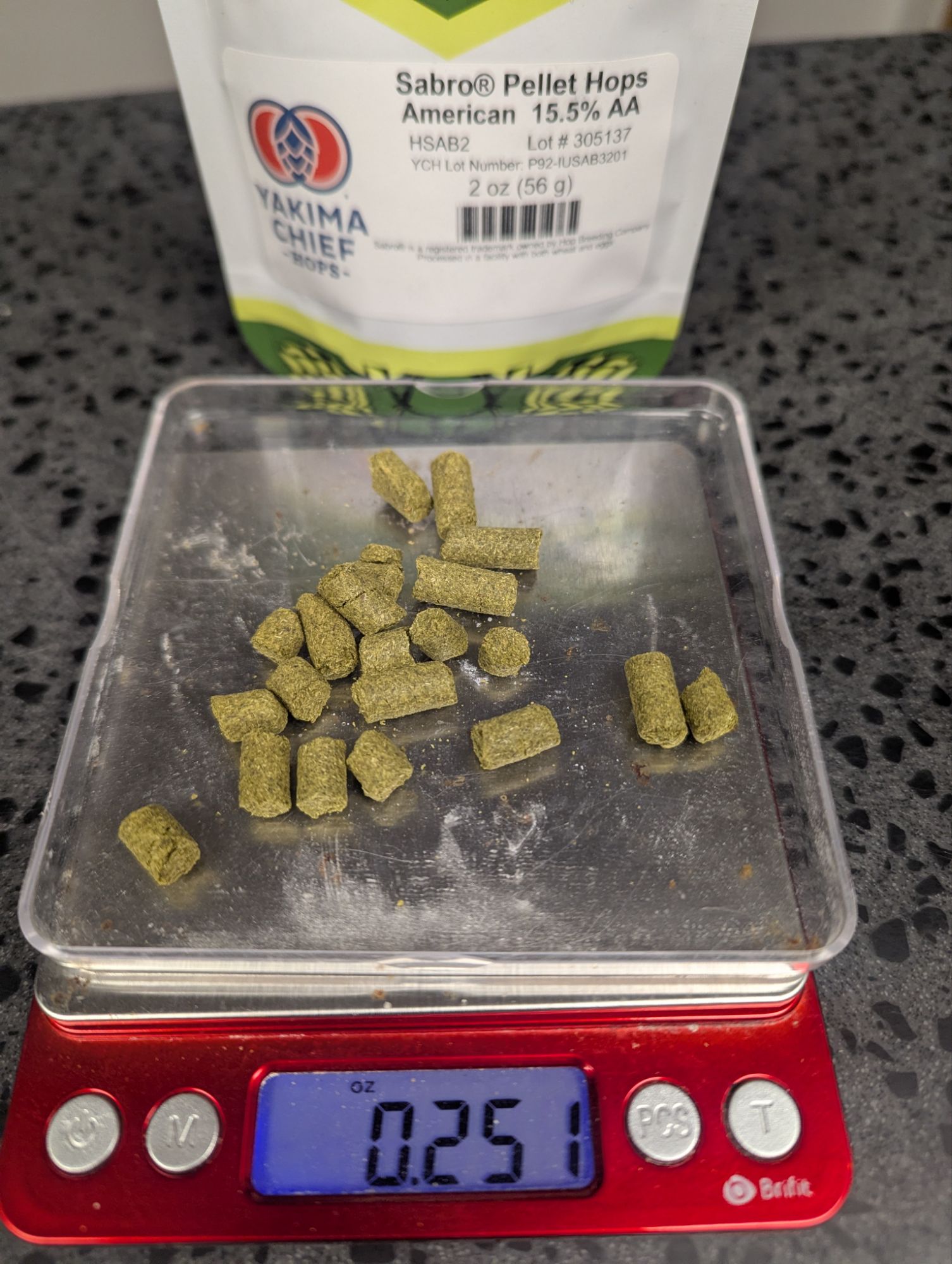

@8:12 the wort started to boil and the timer was started. This is a pretty simple brew and my first add is with 10 minutes left in the boil and it isn’t even hops. @8:57 I added in the wort chiller and then @9:02 I added in the Irish moss and yeast nutrients. Pulled a wort sample and got a 1.044SG with 5.75g(21.7L) @9:12 started the chiller and got the wort to 170F(76.6C). @9:14 the wort was down to 170F(76.6C) and added the hops. @9:24 started the chiller up again. Occasionally stirring the hop basket to make sure we pull the most of of them. @9:45 the wort hit 75F(23.8C) and transferred over to the fermentor. While transferring I was pumping in air through a HEPA filter and once fully transferred, @9:55 pitched the yeast. Placed a few ice packs under the cover to chill the wort down a little more. Like to hit around 68-70F(20-21C) before fermentation kicks up fully.

[…] Here is the brew day here […]