As most of my Brew days start off the night before. Making sure I have everything needed, collect the water, and mill the grains. Setup my Anvil Foundry on a delayed brew so when I get up the water should be around strike temp. Brew Session on Brewersfriend

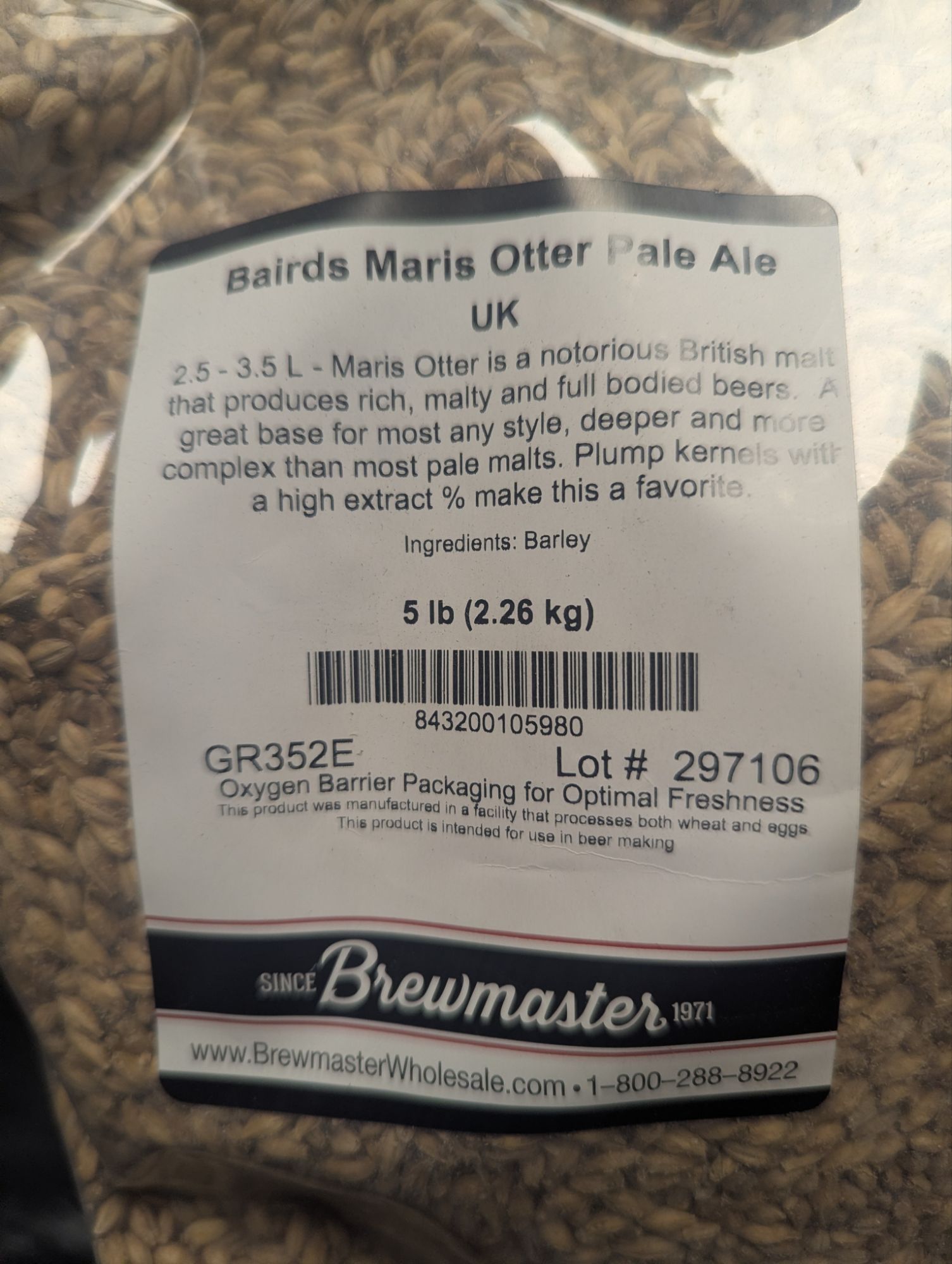

Hit the 150 strike temp and added in the grains. With this system I don’t feel the need to go above and let the grains cool the water down to the mash temperature. I just add the grains when I hit mash temp and let the system regulate the temperature. I will drop the power to about 80% when I do this. Mash for about 60 minutes. Right around 10 mins left in the mash I raise the temp to 168F to start the mash out process. Waited about 10 mins and pulled the grain basket. Let a good majority of the wort drain out and then I pull the basket and set it at an angle, which for me seems to help really get all the wort out along with a few good squeezes. Took a reading and got pre-boil gravity of 1.041 which is 2 points lower then I had calculated out. Also a little more wort then expected so that is probably why I’m down 2 points.

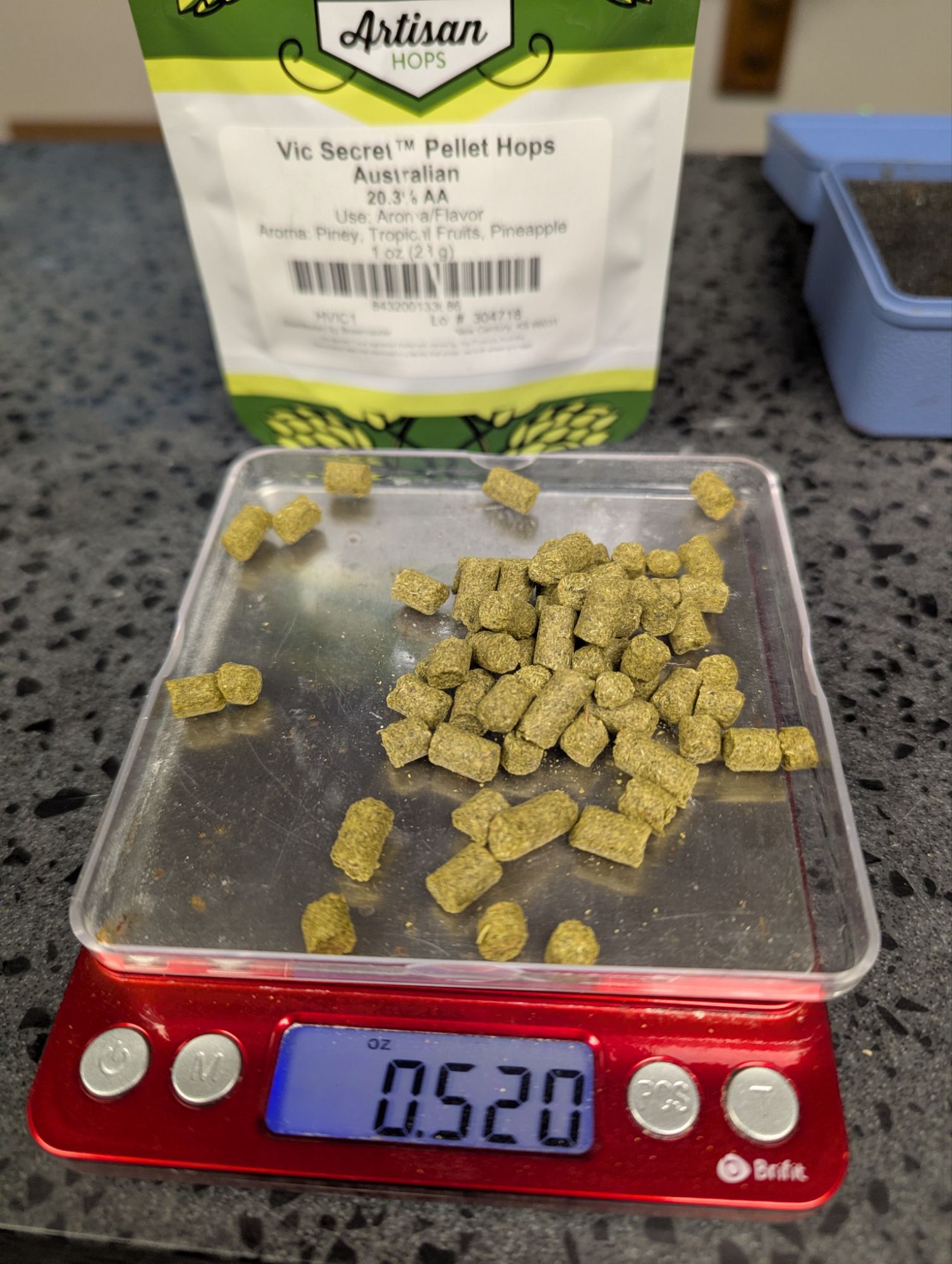

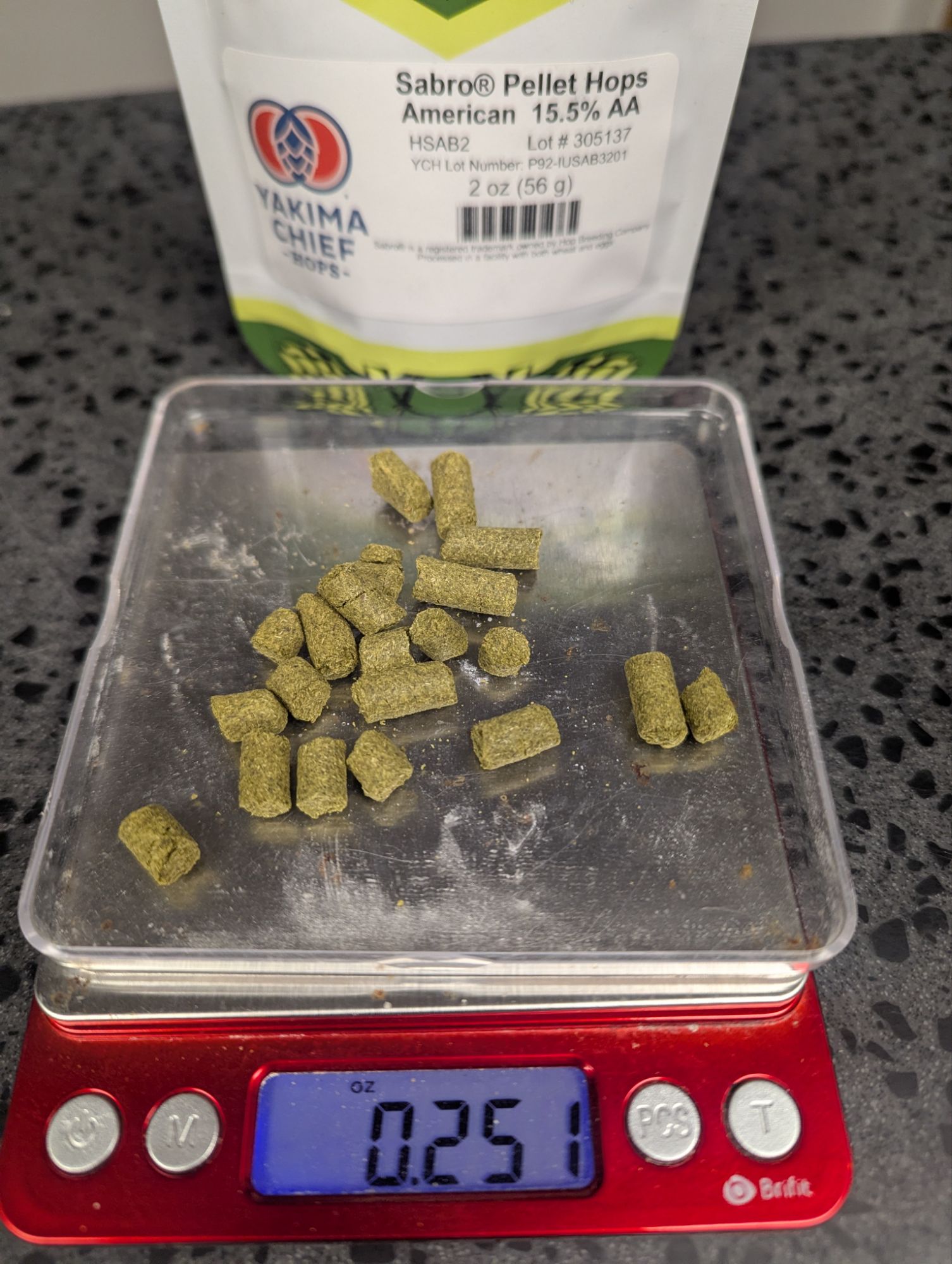

Pulled about 2 cups of hot break, inserted my hop spider and waited to hit a boil. After about 30 mins into my 90 min boil I started to add in the hops per the schedule. Chilled wort down as quick as I can to around 70-75 as my water comes off the tap at around 58 degrees this time of the year. 8)

Pitched yeast and put in my ferm chamber and set at 62 degrees. Started to use a new Cold Crash Guardian stay tuned for a more in depth on that. Gravity ended up being only off a point and came in at 1.048.

As you probably read in my past brew days I always for get to get the end pictures but today I didn’t and got them. Additional I thought Id show my clean up as well. I have a nice sink in my back room as i’m in the basement brewing away. Was going to get tossed at work so I saved it and also saved me a good $400+. I start my cleaning with all the small stuff I have. I hang my hop basket to let drain a little more while I wash my chiller coil. That I have always found to clean first and get everything off asap and it makes it a lot easier to clean. I have a bucket in which I store a lot of these small items so get the rest cleaned up but first I dump the hop material in a bag to be tossed. With two dogs no need them getting into that. From there onto the Anvil foundry, my after user consist of first spraying it down and letting it sit while I clean everything else. I blast all the heavy material, which isn’t much out, then to a scrub with water and Dawn. Dry it up and put it away. I’m do for a good cleaning and soaking which I have been doing once a year on this Anvil. More to come on that too. 8)