So the other day I was looking at an old humidifier and said, hmm I need a glycol chiller, I wonder. A humidifier is bascially a window AC unit but the part that sticks outside is all inside. I started to think on how I can make this all happen. I had a cooler I wasn’t using and had used as a poor mans chiller in the past by placing ice water and pumping that around to the fermentor and kept replacing the ice, didn’t last long like this. With that I know I had a storage vessel for the glycol mixture now just needed to figure it all out, from there I went to town.

I quickly got the humidifier on my bench an stripped it down the the basics. Be careful doing something like this, there are things in the items inside that can harm you so knowing the basics is a good start. Once I had the entire system stripped down, keeping the refrigeration system fully intact, I started to figure out what I wanted to do.

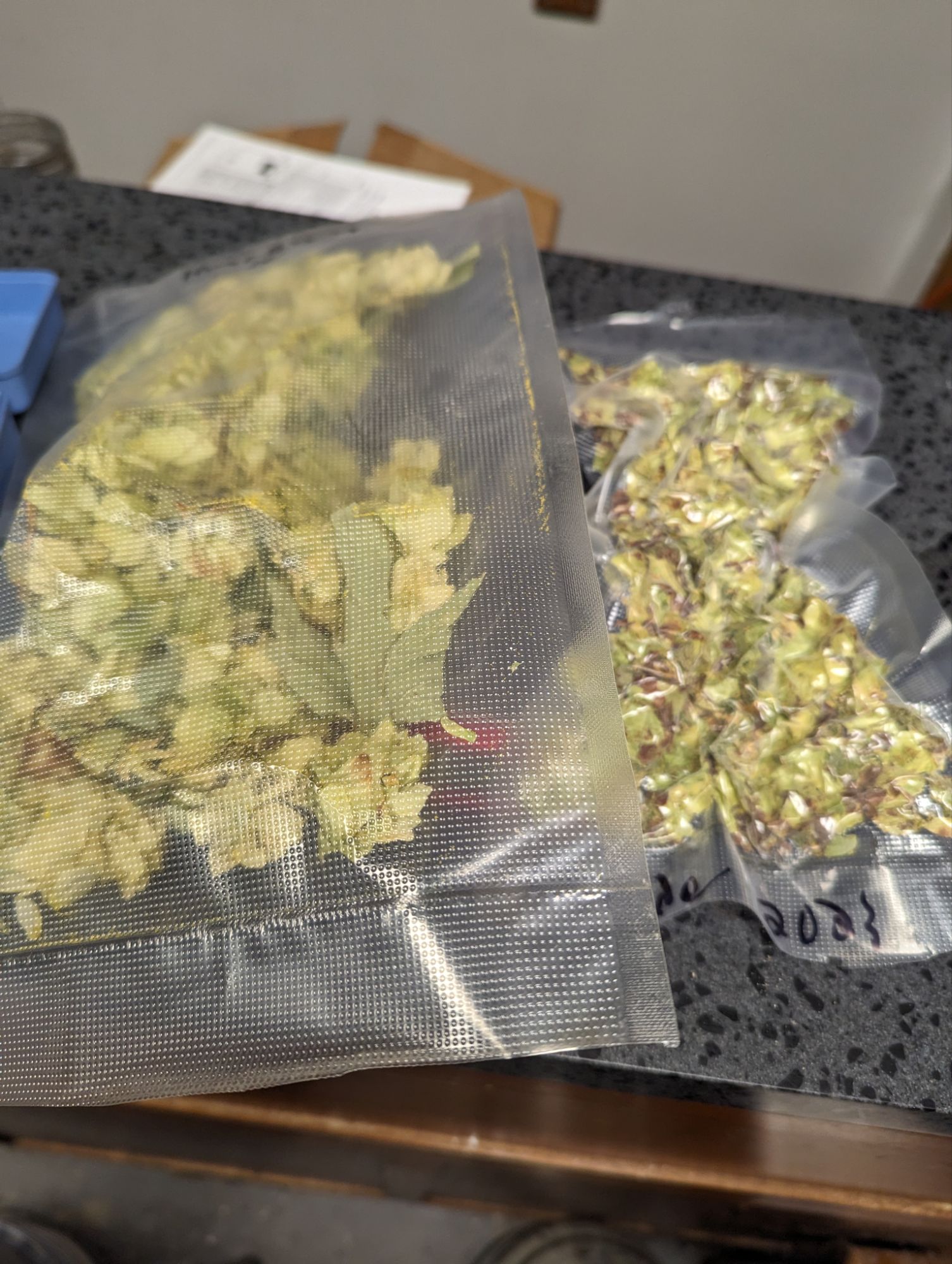

Once I had the dehumidifier all stripped down I know what I had to work with. At this point I had thought maybe let me reclaim the refrigerant and pipe in how I want to but decided, let me give the pipes an easy bend and see if I can manipulate the evaporator coil away from the condenser coil. I was able to separate it out enough to put the evaporator coil in the cooler full of water. I had created the most simple chiller I could at this point. I had the evaporator coil in water and compressor and condenser coil on the outside. I had decided to mount the compressor back on the humidifier base as it was already setup to accept the compressor and coils. Once mounted on the base I wired up the condenser fan and compressor to a plug to perform some testing to see if this will work with a Ink bird controller to turn the compressor on and off. I ended up running the sensor in the evaporate coil and set to 36F (2.2C). This way since I was running water the coil temp wouldn’t get below freezing. Was able to squeeze out 34F (1.1C) and it maintained. With that I figured out a few things, I need to keep a pump running and water moving around the cooler or the coil will ice up, won’t be a problem with glycol but still will need to move the glycol around to ensure good cooling of the fluid. Also found that there needs to be a delay and a temperature differential greater then 2 degrees to reduce short cycling. I want to ensure I get good oil return.

During the testing I started the water off at 90F(32C) and let the chiller run for a few days. I pulled it and maintained 60F(16.5C) no problem. From there I was happy with it and decided to see how far I could cold crash it. Started off at 60F(16.5C) at around 15:00, when I woke up the next morning at almost 5:00 it was down 50F(10C). So with the straight water I was very happy with the performance of this chiller. Once I can get glycol into the system, Ill be able to drop the water temperature down to the 20ishF(-16ishC) which will help with the heat transfer.

Up to this point I haven’t spent a dime which is right where I wanted to be with this project. I had a cooler, I did pay $15 for it back last year and the humidifier was free, my mom was tossing it.

Now that I know it runs time to make this thing so I can move it around. I happen to have a piece of 3/4 plywood that was almost the right size so went to Home Depot and purchased 6 casters ($20) and mounted them on the 3/4 plywood. Now I have a mobile cart and placed the cooler on and secured in place with some angle brackets I had in my misc draw, I only screwed into the wood as I didn’t want to create holes in something I want to hold a liquid 8). Placed the humidifier on and adjusted so it would sit nice and give me room for the control panel. So now I have a working model and its movable. I’m making progress here, Next its time to control this thing and what should I do for that.

So with keeping costs in mind I looked around my storage room for a thermostat that would work on this. I didn’t have anything and thinking about it, I really want to create something custom here as I want to control a pump and also a compressor and insuring I protect the equipment from damage as well. With all that in mind, I decided to create my own controls for this and to make it even cooling doing it all via wifi. I did have sensors and esp8266’s laying around so I thought, I always wanted to make my own project, lets check this out.

Starting off on writing the code, I started with bring on the sensors on a web page, from there I added in set point and relays to control the pump and the compressor. In regards to keeping the humidifier from freezing the coil, I had a coil sensor which runs the compressor and a water sensor to run the pump. If the compressor is running the pump is running and if the temperature is outside the water set point it will run. I did add a 10 minute timer on the compressor to prevent short cycling and also added in a 2 degree differential. Currently the entire project is in Fahrenheit but may eventually add in the ability to go between F and C. I do have a nice line under Keeping it cool that shows the status. I was thinking down the road I can add a scrolling mini screen on the chiller itself that displays that status line.

From the coding I added on the components that I needed to the esp8266 and once fully tested on the bench, I let it run and maintain the water temperature. I wanted to keep the controls as simple as I could but yet make it easily swap able if something fails. Wired up the relays to a duplex that I cut the hot tab to be able to supply two different relays to two different outlets. One for the pump and the other for the compressor.

Test ran the unit with the new controls and it worked as planned, I’m very happy with the setup so far. I haven’t fully decided how I’m going to handle the fermentor control yet, if its just my anvil thermostat running the pump or I’m I going to make a fermentor module for my controls so I can just plug in a module and have the fermentors on the same web interface as the chiller. I haven’t devices on this yet, more to come. Either way I have my glycol on order and will be using this on a future brew, especially during the summer months. I do plan on playing with the code some more to make it easier to follow and also allow for some other features for easier setup. Once I’m done with the code, I’ll probably post on github and I’ll add a link.

Overall pretty cool project to do and didn’t cost me a lot. I have my son and daughter helping on this project so it was nice to have the extra hands and always fun doing things with your kids, BTW mine are 21 and 15.