I really digging this idea of brewing these 2.5 gallon batches and just moving them right into can to can condition all these smaller batches to have more beer in cans but yet also have the kegs too. 8). So with that said onto the brew day. The day before I started to collecting the water in hopes my ingredients show up the day before. I added in the salts required by the recipe. Woke up the next morning and milled the grains.

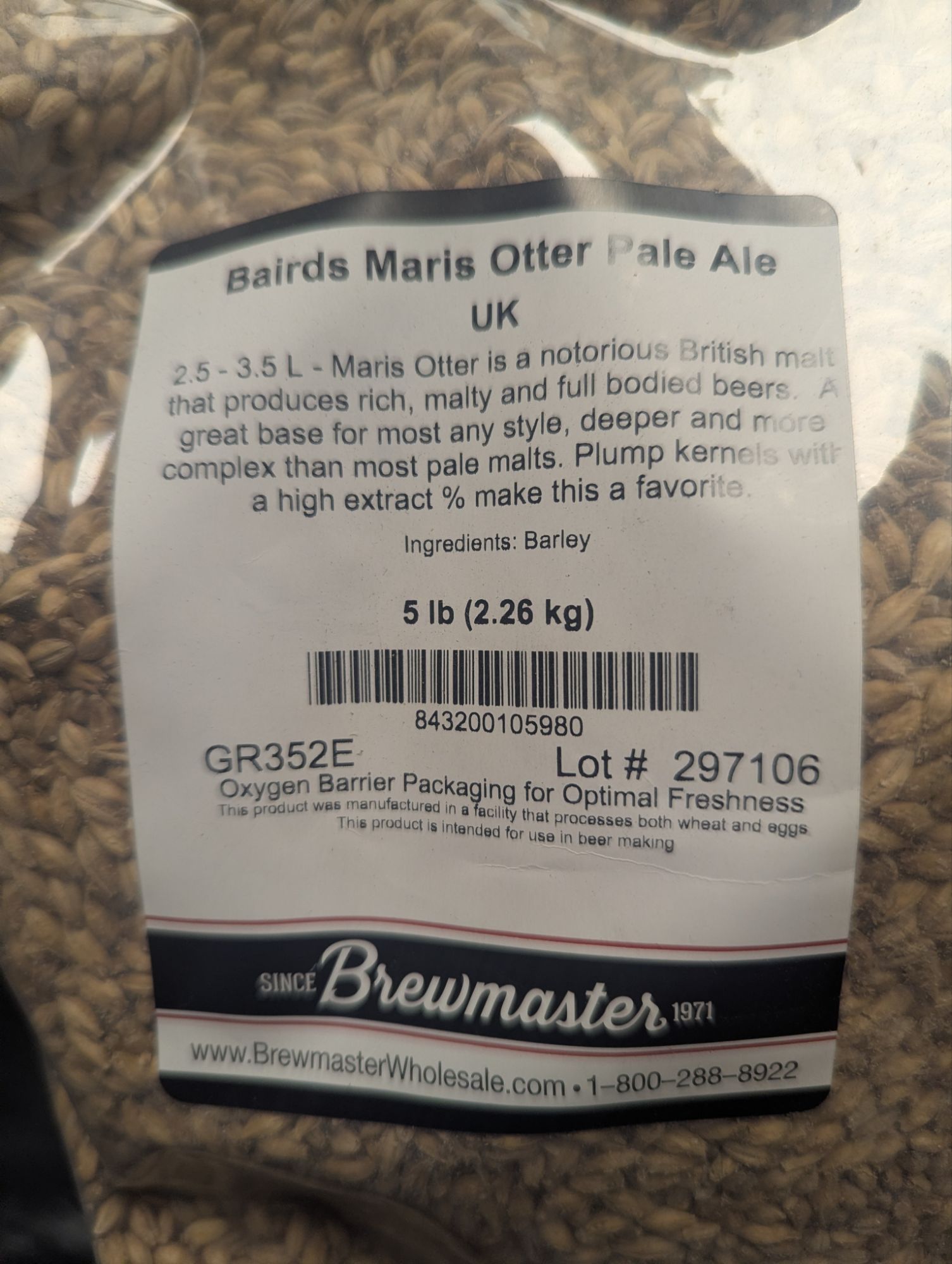

Once we hit the dough in temperature of 158F(70C) I added in the grains and started the mash timer. Added in the pump and started to flow. 30 minutes into the mash I stopped the pump and gave the entire mash bed a good stir. @7:34 with a little over 7 minutes left int he mash I turned the Anvil up to 168F(75.5C) and 100% power to mash out. This just saves me a few minutes and really not loosing or gaining anything that I can tell. My efficiency did not change doing this so I continue. @7:38am was up to the 168F(75.5C). @7:43 I pulled the grain basket and cleaned up the pump and the items no longer needed while awaiting the mash to get up to a boil. Pulled a gravity sample of 1.037SG and about 3.8G(14L). @8:04 hit 200F(93.3C) and I pulled my typical 1 cup(.23L) on 2.5G(10L) batches. @8:14 the boil started.

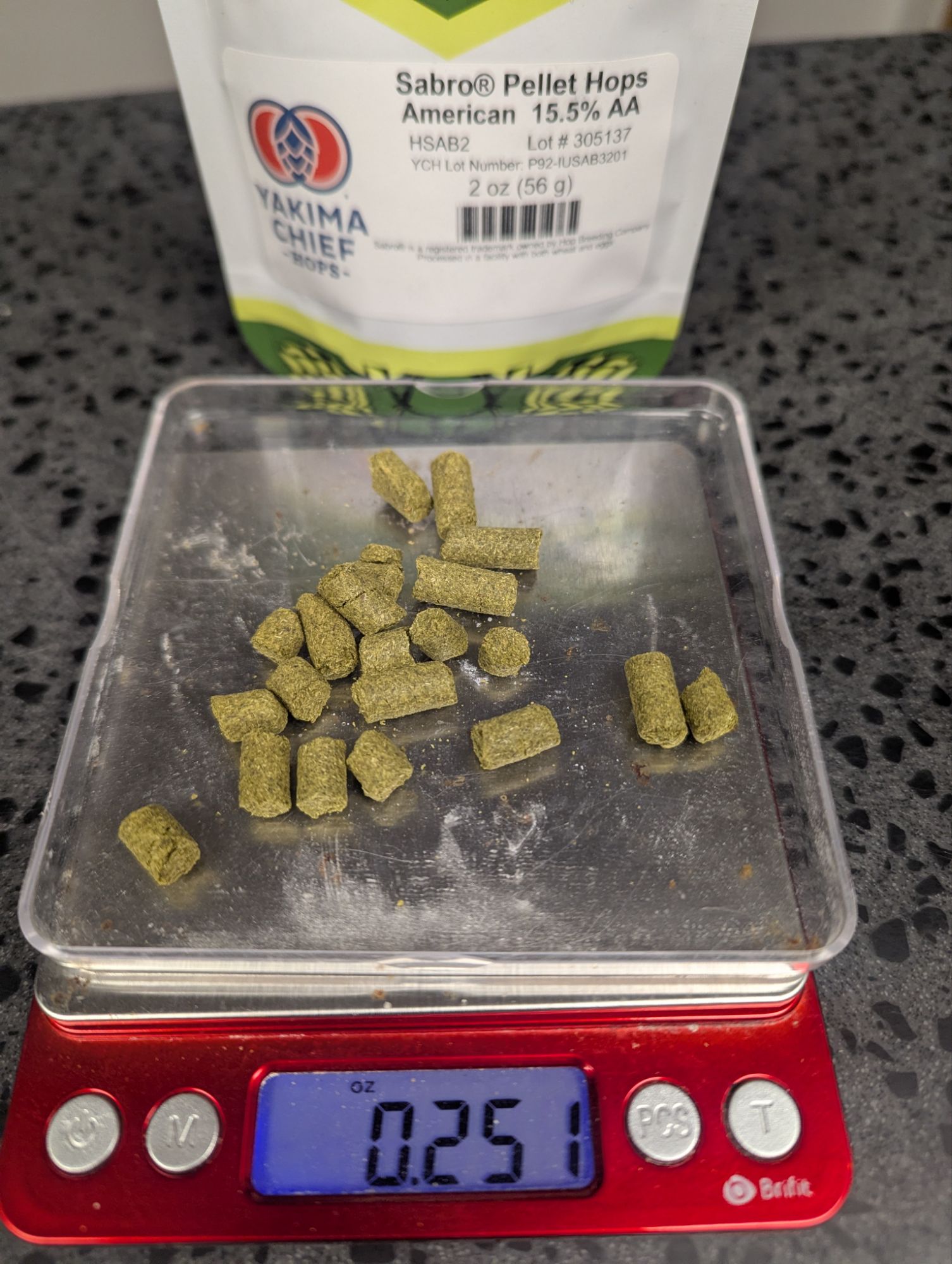

This is one of my favorite beers to make as its relaxing. I still do the 60 minute boil as I feel it does add something to it, being ever so minor but something, including the color. Once the wort starts to boil its just sit back and relax till you have to get ready to chill. @9:00 added in the wort chiller and waited for the 10 minute mark to add in the Irish moss and yeast nutrients. At the end of the boil I pulled a gravity reading of 1.037SG and had about 3.2G(12L). @9:15 after chilling down to 170F(76.6C) and added int he whirl pool hops for 10 minutes, the temperature settled out at 162F(72.2C). @9:25 continued the chilling. I would occasionally stir the hops in the basket to ensure the oils get pulled out and don’t just saturate inside the basket. Its pretty cool you can see it dispense into the wort. @9:36 wort was down to 72F(22C). Transferred to the fermentor while pumping in air. Once fully transferred I pulled what ever was left for an experiment into a 5L flask. Pitched the yeast and placed in a cool dark place to ferment. Cleaned up the equipment completed by 10am.

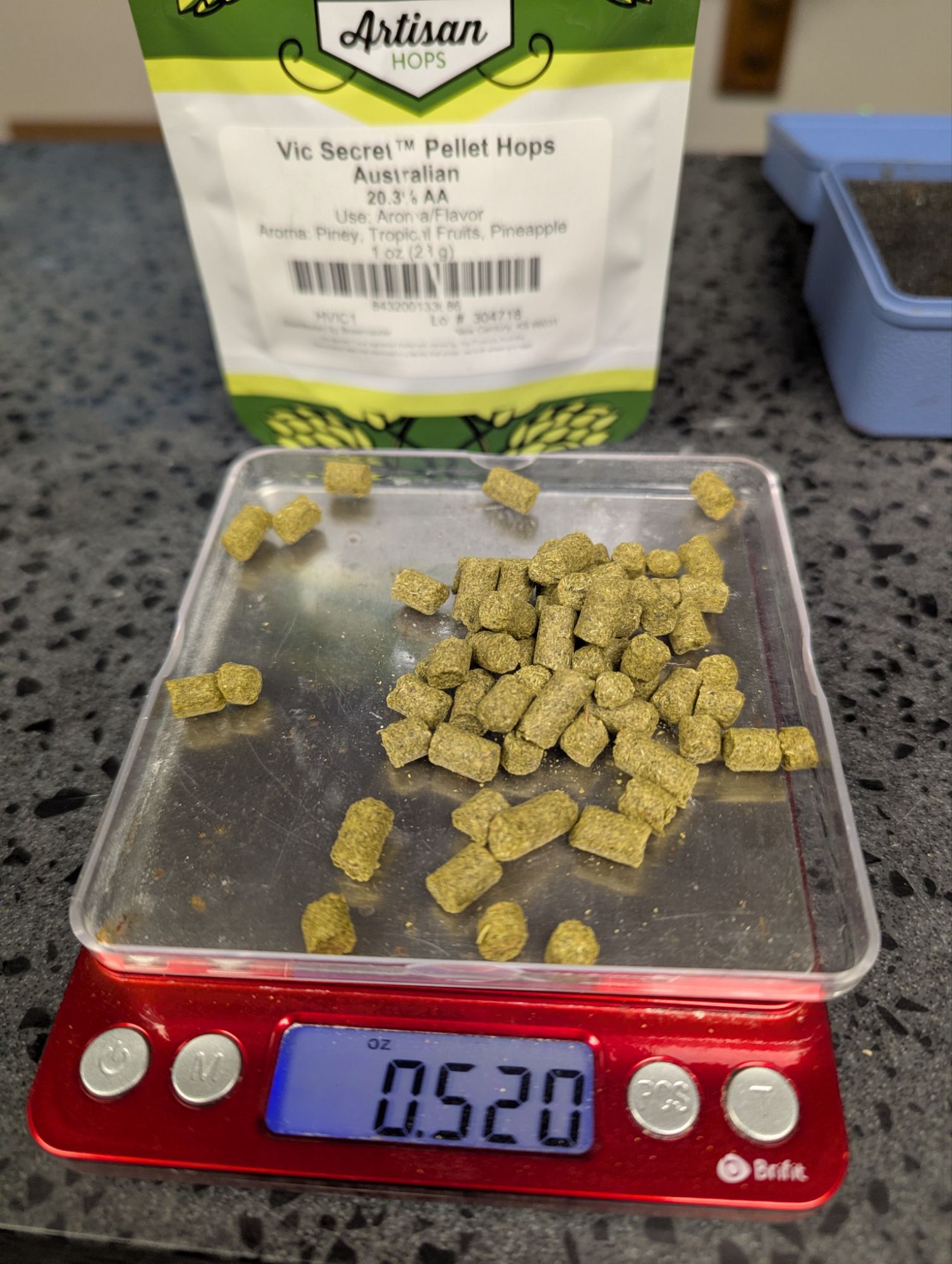

After a day and a half of fermenting I had added in the dry hops to the beer and let it rest for the rest of the week with some heat on it to maintain 68F(20C). Took at gravity reading after the week and got a 1.008SG. Placed the fermentor into my chest freezer to cold crash it before tossing it into some cans to carbonate.